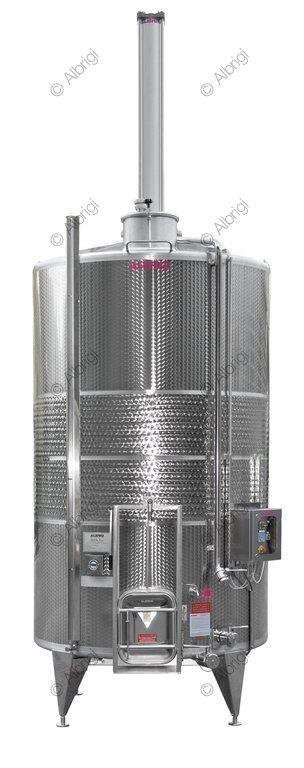

MONOFOLLTANK

USE

The Monofolltank is a simple, automatic fulling mechanism equipped with a self-rotating single blade driven by a pneumatic piston. It can be applied to small and medium-capacity tanks, with the possibility of adding thermal conditioning and an insulation gap on request.

FEATURES

- Automatic Fulling: Fulling system with a pneumatic cylinder moving a fulling blade.

- Automatic Rotation: The blade rotates slightly as the cylinder rises, ensuring uniform mixing of the husk cap.

- Robust Material: Constructed entirely of AISI 304 stainless steel, with food-grade high-density polyethylene fittings.

- Ease of Installation: Adaptable to existing tanks, either open ever-full type or closed with central manhole.

- Electronic Control: Equipped with a control unit to set manual or automatic fulling cycles, with adjustment of speed, pressure and sequence of cycles.

ADVANTAGES

- Product Quality: Guarantees gentle fulling of the skins, without crushing them, preserving the quality of the wine.

- Operational Efficiency: Automates the fulling process, reducing manual work and improving productivity.

- Flexibility: Suitable for tanks of different capacities, from 20 hl up to 300 hl.

- Safety: The design avoids direct contact between moving parts and the tank, preventing damage to the skins.

The Monofolltank is ideal for wineries in need of an efficient and safe fulling system for small and medium-sized tanks. Its robust construction, electronic control and adaptability to existing tanks make it an indispensable tool for improving wine quality and operational efficiency.

Disponibilidade:

Somente sob pedido

- fermentação

- processamento

*Para ver o vídeo você deve aceitar a política de cookies

IT

IT

EN

EN

CN

CN

FR

FR

DE

DE

RU

RU

ES

ES

AR

AR

NI

NI