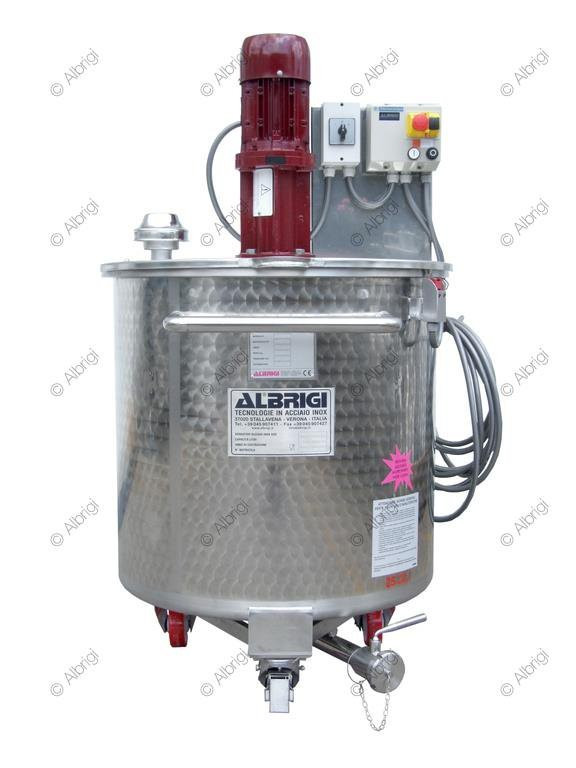

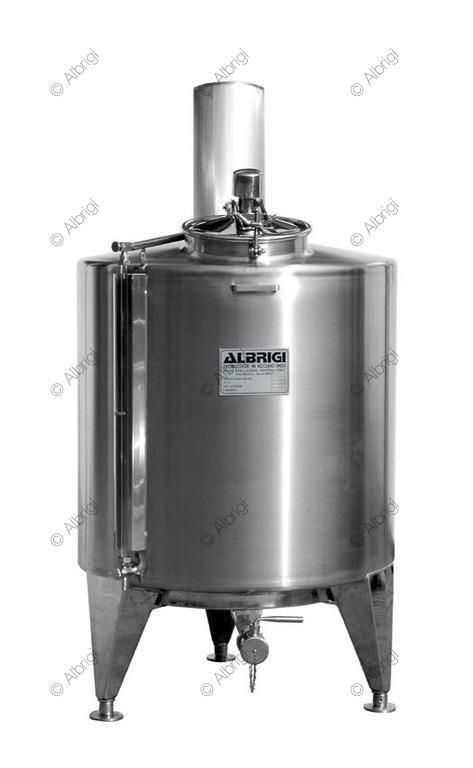

FARMATANK

USE

The Farmatank is an AISI 304L or 316L stainless steel tank designed for the storage and processing of raw materials for the pharmaceutical industry. It can be insulated and thermally conditioned, and is supplied with air conditioning and insulation to work in aseptic environments. It is equipped with a specific agitator to mix different types of product and can operate under pressure or vacuum conditions.

FEATURES

- High Quality Materials: Constructed in AISI 304L or 316L stainless steel, with internal finishes suitable for working in aseptic environments.

- Thermoconditioning and Insulation: Equipped with an interspace for steam conditioning, glycol solutions or sealed, and insulation to maintain controlled temperatures.

- Operational Versatility: Can work in pressure conditions up to +10 bar and absolute vacuum, with a temperature range of -20°C to +120°C.

- Specific agitator: Supplied with agitator to mix various types of product, ensuring a homogenous and controlled process.

ADVANTAGES

- Process Efficiency: Designed to optimise storage and mixing processes in pharmaceutical environments, ensuring product quality and safety.

- Precise Control: Thermal conditioning and insulation allow precise temperature control, improving operational efficiency.

- Robustness and Durability: Stainless steel construction and high quality finishes ensure durability and resistance to the harshest operating conditions

- Adaptability: Versatile and adaptable to different process requirements, from absolute vacuum to high pressure.

The Farmatank is ideal for the pharmaceutical industry that requires reliable tanks for storing and processing raw materials. Its versatility, precise temperature control and ability to operate in aseptic environments make it an excellent choice for optimising production processes.

- mischen

- Kühlung

- Heizung

- Lagerung

IT

IT

EN

EN

CN

CN

FR

FR

PT

PT

RU

RU

ES

ES

AR

AR

NI

NI