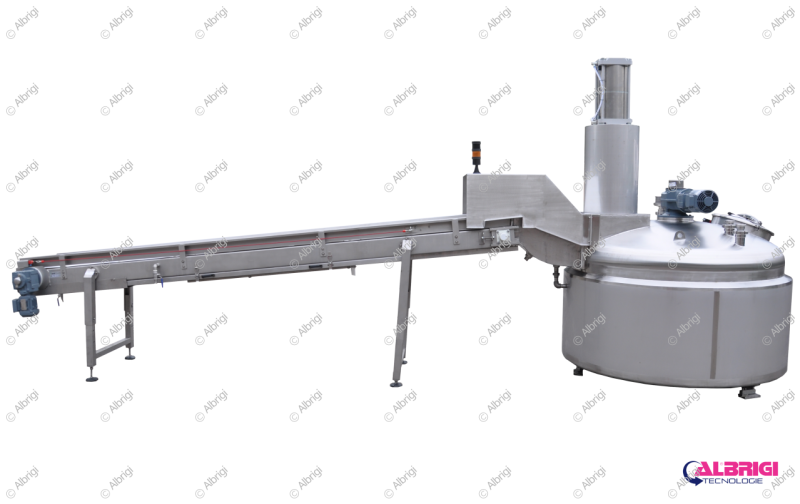

MELTER FOR BUTTER, MARGARINE, AND HYDROGENATED FATS

USAGE

The melter is a tank designed for the controlled melting of butter, margarine, and hydrogenated fats, ensuring an efficient, uniform, and safe process. Thanks to its optimized heating system, it rapidly melts fat blocks without altering their organoleptic properties, maintaining a constant temperature and ensuring optimal homogenization of the product. It is ideal for applications in the food, confectionery, and dairy industries, where liquefied raw materials are essential for subsequent production processes.

FEATURES

The melter is a highly customizable tank, manufactured to customer specifications to meet specific production needs. It can be made from AISI 304 or AISI 316 stainless steel, depending on the required level of corrosion resistance and compliance with sanitary regulations.

The structure consists of a thermally conditioned and insulated vertical cylindrical tank, supported by four adjustable stainless steel legs for stability and easy installation. The conical bottom with a central total discharge outlet ensures complete drainage, avoiding residues and contamination. The semi-opening lid allows easy access for material loading and maintenance.

The high-efficiency heating system includes a pillow-plate thermal jacket, inflated at operating pressures of 3 to 5 bar, ensuring even heat distribution. Additionally, the melter can be equipped with a removable stainless steel coil, positioned at the top of the tank, allowing heated water circulation for efficient fat melting.

For precise process monitoring, the melter can be fitted with temperature sensors, a double-effect DN 50 air vent, a total discharge spout, and a thermowell for temperature probes. The thermal insulation is made of mineral wool treated with thermosetting resins, with an externally welded stainless steel sheet casing, ensuring maximum heat retention and energy efficiency.

ADVANTAGES

- Customizable tank, built to customer specifications.

- Fast and uniform melting, without altering product quality.

- Precise temperature control, with an efficient and adjustable heating system.

- Hygienic and durable materials, made from AISI 304 or AISI 316 stainless steel.

- Easy use and maintenance, with an optimized design for loading and cleaning.

- Total discharge and draining design, to prevent waste and ensure continuous product flow.

- Advanced thermal insulation, reducing heat dispersion and improving energy efficiency.

The melter is a tailor-made solution for food, confectionery, and dairy industries, requiring a safe and hygienic system for melting butter, margarine, and hydrogenated fats. Thanks to its modular configuration and customization options, it perfectly adapts to production needs, improving efficiency, operational continuity, and process quality.

- mixing

- heating

IT

IT

CN

CN

FR

FR

DE

DE

PT

PT

RU

RU

ES

ES

AR

AR

NI

NI