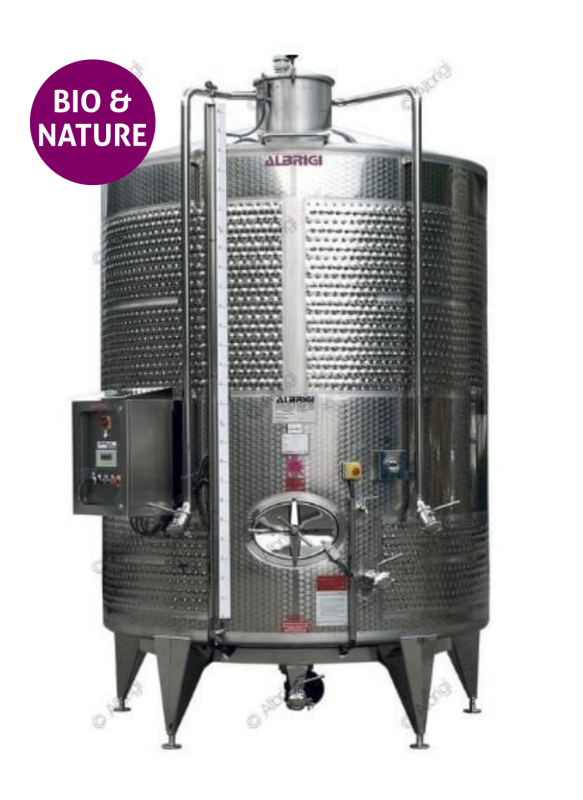

BATONTANK

USE

The Batontank is an automatic fermenter and batoner tank designed to simplify and improve bâtonnage operations and other winery activities. Thanks to its innovative system, this tank saves time and energy while ensuring optimal management of oenological processes.

Designed to maximize the effectiveness of natural fermentation processes, the Batontank is ideal for producers of natural, organic, and biodynamic wines who seek to get the most out of their production while preserving the purity and authenticity of the wine.

FEATURES

- Patented rotating blade system: The Batontank is equipped with a rotating blade on the bottom which, activated at regular intervals or when needed, facilitates various oenological operations, saving time and energy.

- Versatility of Use: Ideal for homogenising the temperature of fermenting musts, reducing the cooling time of newly produced musts, blending wines and dissolving chemicals without the use of external pumps.

- Optimisation of the Bâtonnage Process: Allows the noble lees to be kept in suspension during wine ageing and storage, by programming the blade rotation for extended periods of up to 24 months.

- Automation and Programming: Rotation speeds and pulses (pause/work) are adjustable and programmable to adapt to different operational needs.

- Energy Efficiency: Helps reduce energy and labour consumption while improving the quality of the end product.

ADVANTAGES

- Time and Energy Savings: Bâtonnage operations and other cellar activities are automated and simplified, saving time and effort.

- Improved Product Quality: Thanks to the continuous and controlled handling of the lees and the homogenisation of the musts, a higher quality end product is obtained.

- Adaptability: The bâtonnage system can also be applied to existing tanks, making it a versatile and cost-effective solution for wineries of all sizes.

The Batontank is mainly used in bâtonnage operations, but is also ideal for other uses in the winery, such as homogenising the temperature of fermenting musts and rapid cooling of newly produced musts. The main advantages include significant time and energy savings, reduced labour requirements and an overall improvement in wine quality due to optimal lees handling.

- fermentation

- mixing

- refrigeration

- heating

- storage

IT

IT

CN

CN

FR

FR

DE

DE

PT

PT

RU

RU

ES

ES

AR

AR

NI

NI